Carbon Neutral Energy

From Waste Heat

Our patented QHT - Qpinch Heat Transformer - transforms waste heat into carbon neutral process heat, with no electricity consumption, providing the best financials within its technology category.

Award winning

About Qpinch

Qpinch enables large scale processing plants reduce their CO2 emissions and improve energy efficiency. Our fast implementation track with actual value creation, will also free up budget for long term energy substitution or carbon capturing projects. Double win!

It’s elementary: converting waste heat into industrial process heat

Capturing waste heat

Steam, hot liquid and vapours contain a lot of residual energy that is now released in the atmosphere – either directly or via cooling. The QHT can absorb waste heat down to 80 °C.

Transforming waste heat

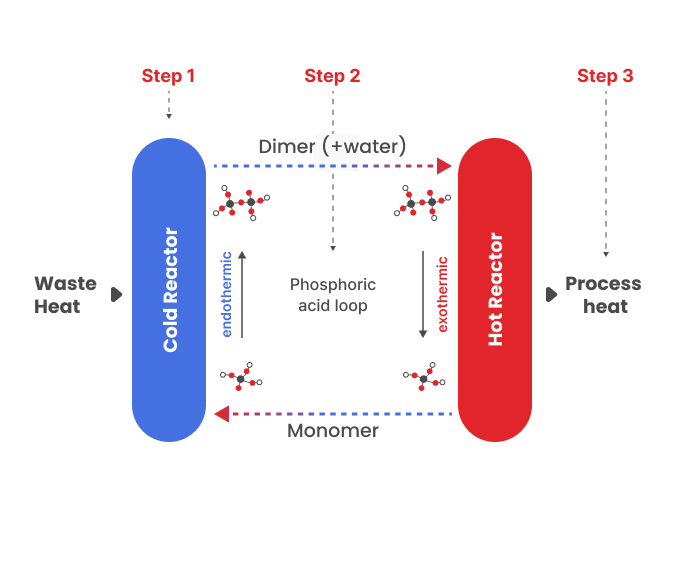

The captured low temperature waste heat is transformed into high temperature process heat, using a physicochemical reaction. No electricity is needed to drive the temperature lift.

Delivering New Energy

We recover 50% of your residual heat and transform it into new process heat with temperatures of up to 210 °C. Our technology is applicable on megawatt scale.

Reduce carbon footprint while increasing operating margin.

High scalability

High temperature jumps

Low net OpEx

High flexibility

Industry leaders with commercial installations

The industries we serve

Refineries

Petrochemical

Carbon Capturing

Food and Beverage

Recycling

Get inspired

Get inspired

Related Blogs

Contact

Talk to a Qpinch engineer

We are a technology partner, so your team may have specialized questions that need answering. Questions related to chemistry, decarbonisation strategy or economics: we are standing by.